Rheocasting can be used to take advantage of the unique properties of aluminum. Rheocasting has a number of advantages over other methods of manufacturing, including shorter production times and better finished product characteristics. In the not-too-distant future, an EDiM semi-solid die-casting cell will be installed at the company's Quero plant in Brazil.

EDiM has acquired rheocasting equipment with the assistance of Bosch, allowing the company to make a significant investment in a technology that is not yet widely used in the market. The partnership with a Swedish company that owns the patent for the technology allowed them to achieve their goal more quickly. Sweden is one of the most advanced European countries in this area, and this partner will provide EDiM with the assistance it needs to complete the project in the most efficient manner possible. EDiM will be able to use this assistance to improve the efficiency of thealuminum die castings. In order to follow the Rheocastingzinc alloy die casting on a national level, the University of Padua will place a materials engineer in the company who will conduct research and write a thesis on the subject matter. EDiM continues to invest in cutting-edge solutions that provide measurable and tangible benefits to their OEM customers, despite the fact that they are operating in a challenging economic environment and facing the challenges of a declining market.

What is the Die Casting Process? The High Pressure Die Casting Processdiecasting-mould.com

What is the Die Casting Process? The High Pressure Die Casting Processdiecasting-mould.com

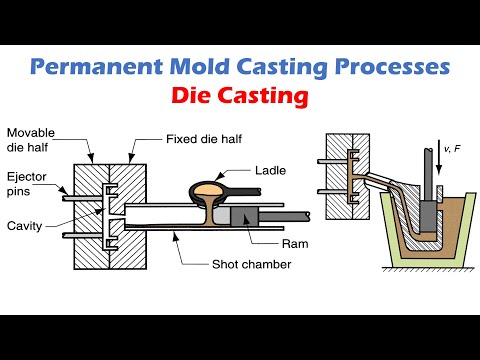

Die Casting - Permanent Mold Casting Processes.diecasting-mould.com

Die Casting - Permanent Mold Casting Processes.diecasting-mould.com

Rheocasting is a term used to describe the process of combining high-pressure die casting with other manufacturing processes. When compared to high-pressure die casting, rheocasting retains the advantages of the former while also introducing new ones. Traditional die casting involves the injection of liquid aluminum into a steel mold at high speeds and pressures, resulting in the formation of a solid mass of aluminum. As a result, an aluminum casting is created, which contains the final products that will be produced. Once the casting has been removed from the mold, the mold is sealed and is ready to be used for a new manufacturing cycle to be started from scratch. When used repeatedly, it can result in significant financial savings, as well as having a lower environmental impact than disposable molds, according to the manufacturer. Die casting is an excellent solution for high-volume production due to its high repeatability and consistency in the manufacturing process. A wide range of applications for this manufacturing technology can be found in the automotive industry, which serves as EDiM's reference sector. Hundreds of aluminum components are found in every automobile, and these components are the company's primary source of revenue. One of the components of a steering box is an engine. Other components include gearboxes, suspensions, and transmissions. Products that can be manufactured using rheocasting techniques are becoming increasingly diverse, not only in the automotive industry but also in related fields, such as telecommunications and electronics.