As a critical component of scientific research, yield optimization, safety assurance, and quality control, cleanroom installation is becoming an increasingly essential element in the production process due to the advancement of technology.

Whatever the purpose of the cleanroom, the potential for dangers means that its design requires the most excellent care and attention from both the departments that will be utilizing it and the design team as a whole. This section will go over the most critical factors to keep in mind while planning and constructing a cleanroom environment.

What Is The Definition Of A Cleanroom?

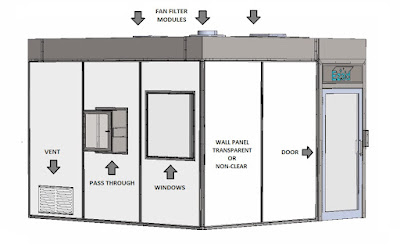

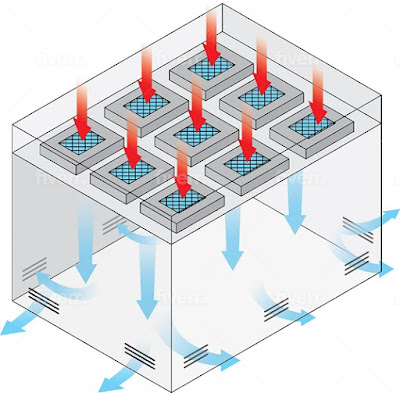

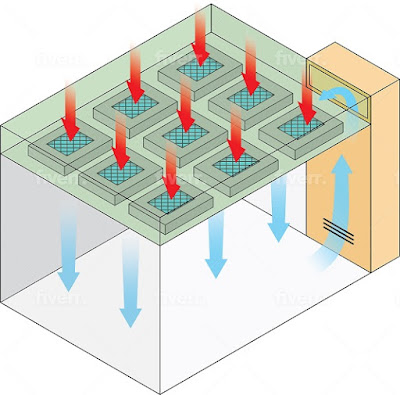

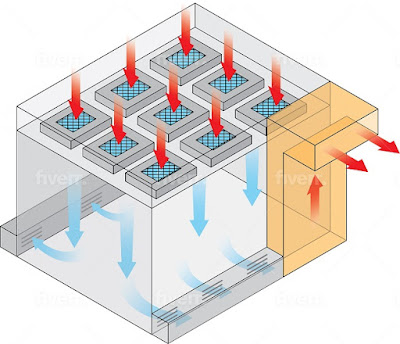

The term "cleanroom" refers to an enclosed area within a manufacturing or research facility designed to control air pollutant levels and other environmental parameters such as pressurization, temperature, humidity, and personnel access, to meet the stringent environmental requirements demanded. Here is the top advantage of Laboratory Modular Cleanroom for you:

Traditional Use of the Cleanrooms

Traditionally, they have been used by various businesses and research institutions, including biotechnology, pharmaceuticals, microelectronics, life sciences, and food packaging, to protect goods or processes from contamination and pollution. These possible pollutants must be managed to guarantee product quality, worker safety, and the integrity of scientific research.

Cleanrooms must be built correctly to minimize contamination, and a set of criteria was created in order to categorize the ability of a specific cleanroom design to reduce contamination. As a result, genuine cleanrooms must adhere to strict standards regarding the quantity and size of particles present in a given air volume.

Cleanrooms Are Classified Into Two Types: Traditional & Modular

As soon as you've determined the requirement for a cleanroom, it's critical to consider the many options for the kind of cleanroom you'll need. Traditional and modular are the two main types into which they may be divided. In spite of the fact that both have their advantages and disadvantages, Modular Cleanrooms are becoming more popular for a variety of distinct reasons.

Changes And Expansions Are Made

If your cleanroom operations need a high degree of adaptability, modular structures provide a much greater degree of modification and extension. Changing or expanding a modular cleanroom is simple and requires just installing extra wall, ceiling, and floor systems. Modular cleanrooms are also more cost-effective than traditional cleanrooms since they need less space and produce less mess or waste. On the other hand, conventional cleanrooms cannot simply be packed up and transported to a new site in the same manner; instead, they must be completely renovated, which necessitates the demolition of existing walls and mechanical equipment.

Cost

Modular construction may be less costly than conventional construction depending on the size and budget of your cleanroom, as well as the categorization and use of the space. Cleanrooms of this kind, for example, may only need a limited amount of space for tasks such as clean storage, resulting in a lower overall cost than a conventional cleanroom.

Installation

Traditional constructions may be a time-consuming procedure that takes months to complete from start to end. Modular construction, on the other hand, is a much easier procedure to complete since all of the components have already been produced. In contrast to conventional cleanroom construction, where walls must be constructed from raw materials, modular cleanrooms need just that the components be built to your requirements. Consequently, it may be completed in a few days or weeks, which is critical for activities that must be up and running immediately.

Similarly, the conventional building will always need the use of construction industry experts. On the other hand, Module cleanrooms may frequently be assembled on-site by your employees, following explicit instructions given by the manufacturer. Additionally, as part of a modular cleanrooms design package, the manufacturer may even provide installation services for a little extra fee.

Creating A Cleanroom Budget Is A Difficult Task

Because each cleanroom design is unique, establishing a budget may be challenging to determine at the beginning of the design process. However, besides the concerns of the cleanroom kind that we discussed above, there are a few more aspects to keep in mind while creating your financial plan.

If you choose a modular cleanroom, you may select from various wall choices that are available at a variety of pricing ranges. For the most part, Softwall cleanrooms will be less expensive than Hardwall or Hardwall cleanrooms in installation and maintenance. Although the latter two may be required if your cleanroom must satisfy the requirements of a rigorous ISO classification, softwall structures may be particularly advantageous for temporary, tiny, or lower-classified cleanrooms.

EZAD Cleanrooms

Telephone: 1-(833) 392-3462

Email Address: info@ezadcleanroom.com

Office Address: 2130 N Glassell St, Orange, CA, 92865

Original Source: https://ezadcleanrooms.blogspot.com/2021/07/what-makes-laboratory-modular.html